-

Het afgietsel van de aluminiumlegering

-

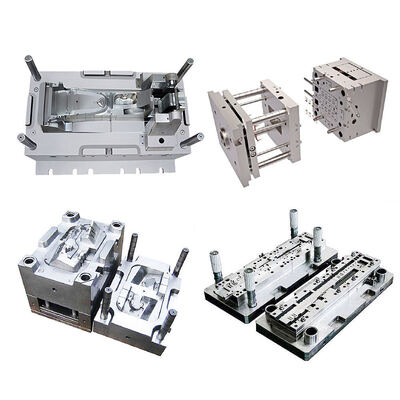

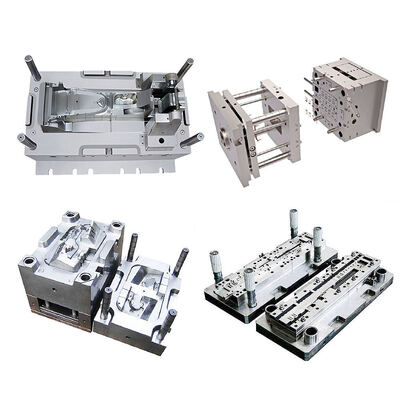

Het Afgietselvorm van de drukmatrijs

-

smelting van metalen mallen

-

Aluminium gegoten matrijs

-

EPS Schuimvorm

-

Verloren Schuimvorm

-

De Vorm van het zandafgietsel

-

permanente mal gieten aluminium

-

Aluminium Gravity Die Casting

-

Matrijs het Gegoten Aluminium Bewerken

-

Autodelenvorm

-

Multi holte schimmel

-

Cilinderkopvorm

-

hoge precisievorm

-

De snelle 3d Drukdienst

-

Greg HenkDank voor uw vriendelijk gastvrijheid. Uw bedrijf is zeer professioneel, zullen wij aardige samenwerking in de nabije toekomst hebben.

Greg HenkDank voor uw vriendelijk gastvrijheid. Uw bedrijf is zeer professioneel, zullen wij aardige samenwerking in de nabije toekomst hebben. -

Lionel LoboGoed bedrijf met de aardige dienst en hoog - kwaliteit en hoge reputatie. Één van onze betrouwbare leverancier, goederen is geleverd in time en aardig pakket.

Lionel LoboGoed bedrijf met de aardige dienst en hoog - kwaliteit en hoge reputatie. Één van onze betrouwbare leverancier, goederen is geleverd in time en aardig pakket.

Precisie elektronische auto-onderdelen ABS-kunststof product op maat gemaakte vormproductie spuitgieten

Neem contact met me op voor gratis monsters en coupons.

WhatsApp:0086 18588475571

WECHAT: 0086 18588475571

Skypen: sales10@aixton.com

Als u om het even welke zorg hebt, verstrekken wij de online-Help van 24 uur.

x| Naam | Kunststof spuitgietmatrijs | Schimmel leven | >1.000.000 schoten |

|---|---|---|---|

| Oppervlaktebehandeling | Warmtebehandeling | Assortiment | Autodeeltjes Schimmel |

| Gemiddelde wanddikte | > 3 mm | Functie | Anti -corrosie |

| Markeren | ABS kunststof auto-vorm,op maat gemaakte auto-onderdelen spuitgieten,precisie elektronische ABS-vorm |

||

Precisie Elektronische Automotive Onderdelen ABS Vorm Kunststof Product Custom Vorm Maken Fabricage Injectie Vormen

Wij leveren missie-kritische Auto Onderdelen Vormen, ontworpen voor de strenge eisen van structurele en semi-structurele automotive componenten. Onze expertise ligt in het creëren van robuuste tooling systemen die consistent onderdelen produceren met uitzonderlijke mechanische integriteit, nauwe toleranties en betrouwbare prestaties onder belasting. We begrijpen dat deze componenten essentieel zijn voor de veiligheid en functionaliteit van voertuigen, en onze vormen zijn dienovereenkomstig ontworpen, met behulp van geavanceerde engineering principes om een vlekkeloze productie te garanderen van zeer sterke, complexe geometrieën die voldoen aan de strengste testprotocollen van de auto-industrie.

Kenmerken

- Ontwerp met hoge tonnage compatibiliteit: Ontworpen met versterkte steunpilaren, heavy-duty platen en strategisch geplaatste interlocks om uitzonderlijk hoge klemkrachten te weerstaan zonder doorbuiging, waardoor de consistentie van onderdelen in grote of dieptrektoepassingen wordt gewaarborgd.

- Superieure ventilatie voor complexe geometrieën: Implementeert een geavanceerd, meerfasig ventilatiesysteem, inclusief perimeteropeningen en speciale vacuümkanalen, om luchtinsluitingen in ingewikkelde ribben, bosses en diepe zakken te elimineren, waardoor verbranding en onvolledige vulling worden voorkomen.

- Duurzame oppervlaktebewerking voor schurende materialen: Speciaal behandelde holtes en kernen met verbeterde oppervlaktehardheid (bijv. door middel van speciale coatings of dubbel temperen) om slijtage te weerstaan van glasvezelgevulde, mineraalgevulde of andere schurende technische kunststoffen die vaak voorkomen in toepassingen onder de motorkap en in het chassis.

- Geïntegreerde sensor gereedheid: Ontworpen met voorzieningen voor het installeren van druk-, temperatuur- en holtesensoren, waardoor real-time procesbewaking mogelijk is en data-gedreven kwaliteitscontrole en voorspellende onderhoudsstrategieën worden gefaciliteerd.

Specificatie

Productnaam | Auto Onderdelen Vorm | ||

Maat | Aangepast | ||

Kleur | Als uw vereisten | ||

Materiaal | Aluminium, Metaal, Als uw vereisten | ||

Toepassing | Auto-onderdelen, Lichtarmatuur, lampafdekking, led-lichtbehuizing, koelplaat of elk ander type spuitgietonderdeel | ||

Service | OEM/ODM | ||

Productontwerp | Aangepast volgens tekeningen of monsters van klanten | ||

Onze Fabriek

Welkom om onze fabriek te bezoeken, we verwelkomen uw komst altijd

![]()

![]()

![]()

![]()

Productieproces

1. Bekijk het onderdeelontwerp, de tekeningen en de kwaliteitsstandaard van klanten.

2. Vorm- en gereedschapsontwerp & fabricage

3. Vorm- en gereedschapstests & bevestig het monster

4. Spuitgieten van ruwe gietstukken

5. Oppervlaktebehandeling: Trimmen, ontbramen, polijsten, reinigen, passiveren & poedercoaten en andere eisen van de klant

6. Precisiebewerking: CNC-draaibanken, frezen, boren, slijpen etc.

7. Volledige inspectie

8. Verpakking

9. Levering

![]()

Toepassing

Geschikt voor de productie van een breed scala aan technische en esthetische automotive componenten. Dit omvat kritieke veiligheidsgerelateerde onderdelen zoals randen voor instrumentenclusters, connectoren voor kabelbomen en componenten voor rem- of brandstofsystemen; evenals grote, complexe onderdelen zoals deurpanelen, achterkleppen en spoilers die een precieze pasvorm en afwerking vereisen. Onze tooling ondersteunt de productie van onderdelen met behulp van technische kunststoffen, composieten en standaard automotive-kwaliteit polymeren.

Onze Voordelen

1. Wij zijn een van de grootste fabrikanten van verloren-schuimvormen in China, we richten ons op uitdagende verloren-schuimvormen en we hebben grote portaalbewerkingscentra, 30 sets geïmporteerde hogesnelheidsbewerkingscentra, meer dan 40 sets algemene machinegereedschappen;

2. We hebben 36 senior vormontwerpers om een redelijk / veilig / efficiënt vormontwerp te garanderen en de snelle vormlevering en rationele vormstructuur te garanderen, waardoor het proces veiliger en de productie-efficiëntie hoger wordt;

3. We gebruiken numerieke besturing machinegereedschap om de vormholtes te produceren, om een gelijkmatige dikte te garanderen;

4. We gebruiken ZL104 Aluminium om de vorm te gieten, om een vorm met hoge sterkte te produceren;

5. Voor de grote vorm gebruiken we Ø22*1 koperen buis als koelbuis, met een watersproeisysteem, om een mooi koeleffect te krijgen;

6. We hebben (TEF10N) coating op het vormoppervlak, het kan de wrijving verminderen, anti-water/statische elektriciteit/zuur-base/hoge temperatuur, hiermee kunnen we ervoor zorgen dat het patroon een glad oppervlak heeft zonder vervorming en gemakkelijk te ontvormen;

7. Alle schroeven die we gebruiken zijn roestvrijstalen schroeven, gemakkelijk te demonteren tijdens onderhoud;

8. Voor de grote vormkist gebruiken we 18-20 mm dikke gesmede aluminium plaat, om een holte met hoge sterkte te bieden;

9. Voor de complexe vorm die moeilijk te ontvormen is, kunnen we de automatische vorm produceren met een uitneemapparaat;

10. We produceren het patroonmonster voor de klant na het afwerken van de vorm, wanneer het patroon gekwalificeerd is, dan doen we een acceptatieklus voor de vorm;

11. We hebben het Hexagon coördinatenmeetinstrument geïmporteerd uit Zwitserland om een test te doen om er zeker van te zijn dat onze vorm gekwalificeerd is.

Bedrijfsprofiel

Luoyang Liushi mould Co., Ltd werd opgericht in 2001, de National Standard Setting Unit voor Lost Foam Casting Mould. Het bedrijf is gevestigd in de Millennium Emperor, pioenbloemstad van Luoyang City. We hebben een kantoorgebouw van 9800 en een werkplaats van 22000, die goed is uitgerust met onderzoek, ontwikkeling, ontwerp, gieterij, bewerking, assemblage, oppervlaktebehandeling en andere apparatuur. Het is een Luoyang gemeentelijk R&D-centrum en technologiecentrum.

![]()

Bedrijfstechnici kunnen on-site begeleiding bieden bij vormassemblage, testproductie, gratis reparatie en complete technologie voor verloren-schuimgietprocessen volgens de eisen van de klant. Met de bedrijfsfilosofie van "zorgvuldig ontwerp, lean manufacturing, beste service, perfecte kwaliteit", streven we ernaar om bevredigende producten en diensten te leveren voor klanten. Na jaren van ontwikkeling is ons bedrijf de voorkeursleverancier van vormen geworden van vele fabrikanten van verloren-schuimgieten en de exclusieve leverancier.

Waarom voor ons kiezen

Specialisatie in technische kunststoffen: Ons team heeft diepgaande ervaring met het verwerken van een breed scala aan hoogwaardige polymeren (PPA, PBT, PPS, enz.), waardoor we vormen kunnen ontwerpen die hun unieke stroom-, koel- en krimpkenmerken optimaal beheren.

Risicobeperkt ontwikkelingsproces: We gebruiken een gefaseerd poortproces met duidelijke mijlpalen voor ontwerpbeoordeling, monstergoedkeuring en proeven vóór verzending, waardoor het projectrisico wordt geminimaliseerd en de afstemming op uw technische specificaties in elke stap wordt gewaarborgd.

Optimalisatie van de levenscycluskosten: Onze ontwerpfilosofie richt zich op de totale eigendomskosten, waarbij de initiële investering wordt afgewogen tegen factoren als onderhoudsfrequentie, energieverbruik (door efficiënte koeling) en componentlevensduur om de beste waarde op lange termijn te leveren.

Coördinatie van het wereldwijde servicenetwerk: We hebben partnerschappen opgezet met vertrouwde technische serviceproviders in belangrijke automotive regio's, zodat u indien nodig toegang heeft tot gekwalificeerde lokale ondersteuning voor onderhoud en probleemoplossing.